company profile

GENERAL COMPANY DESCRIPTION

Executive Summary

Jihan Footwear (Pvt.) Limited is a 100% export oriented Footwear company whose registered office at 64/4 (4th floor), Nayapalltan, Dhaka-1000, Bangladesh and Factory address at Rampur , Burichong, Comilla, Bangladesh. The company was established in 2013 and production started in 2013 with daily production capacity of Espadrille shoes 6,500 pairs per day and leather shoe 8,000 pairs per day and subsequently will be increased to 13,000 and 12,000 pairs per day respectively. To cope with the increasing demand, the management has now decided to expand the existing capacity to 13,000 and 12,000 pairs per day for Espadrille and Leather shoes respectively.

About The Industry

Although Bangladesh export basket is heavily skewed towards RMG export, several new sectors have cropped up over the last decade. Footwear is one such sector which has tremendous potential to significantly boost country’s export while diversifying the economy’s export basket.

Multitude of products

Bangladesh has a host of potential products that can earn substantially large amounts of foreign exchange, if only the necessary patronage from the overseas buyers is given for the sake of expanding the country’s export base and thereby reach a sustainable status for the country’s export trade. Recently, a new opportunity has opened up to further diversify the range of Bangladesh’s export base by including footwear and other leather goods along with the espadrille in the list of exports particularly to the European Union (EU) market. However, the country has already been exporting jute and finished leather and different kinds of jute and leather products to the overseas markets. These products also enjoyed considerable demand because of their high quality. The main reason for this was the natural advantage of jute and leather that Bangladesh produces.

Manufacturing Hub

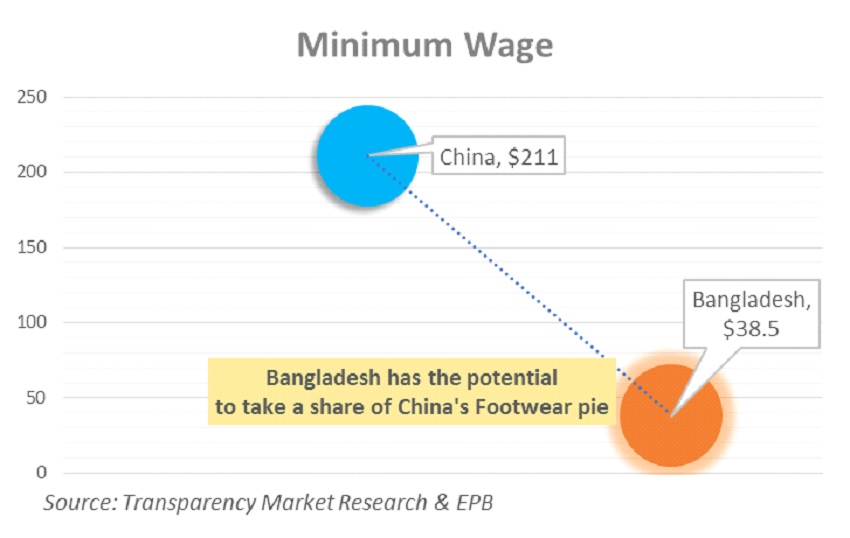

Bangladesh is set to emerge as the next manufacturing hub for the global footwear industry. The cheap labor is prompting top manufacturers to relocate their factories in the country. Growth in exports is due to the low production cost in Bangladesh compared to its neighboring countries: China, India and Vietnam, who also have a very well entrenched leather and footwear export industry. Orders which earlier used to be given to China or India are now being handed out to footwear manufacturers in Bangladesh because they are able to produce low-priced but quality shoes, which have now found its way in to key markets in EU, America and Japan.

Espadrilles Means Eco-Friendly

Wearing espadrilles is an environmental practice with powerful ecological impact. Wide ranges of fabrics, colors, and design specifics or newly introduced manufacturing procedure have been brought in, but the entire design and process are still the same. Since this kind of shoe utilizes completely natural elements, it is very eco-friendly. The manufacturing process of espadrilles takes place without the application of any poisonous chemicals which may be detrimental to the environment. Materials used in espadrilles like rubber, jute, and cotton are made from natural plant. Jute is a vegetable fiber that does not need toxic chemicals and is 100% biodegradable. The natural rubber keeps the espadrilles waterproof and makes it sturdy and long-lasting. All of these natural components grants you a more comfortable walk and is perfect footwear for warm conditions. Also, the light cotton lets the air circulate to keep our feet fresh all day long.

Jihan Footwear’s Export is growing

Jihan Footwear export has been increased day by day and the below chat shows the export status from 2013 to 2022. The company has achieved the foreign currency 12.97,63.11,134.04, 74.03, 96.48, 307.21, 175.77, 454.59, and 1575.98 million BDT in the fiscal year 2013-2014, 2014-2015, 2015-2016, 2016-2017, 2017-2018, 2018-2019, 2019-2020, 2020-2021, and also 2021-2022.

Eyeing the Global Leather Market

As illustrated above, Bangladesh has the potential to accommodate relocating footwear units from China, due to Bangladesh’s inherent input cost advantages.Bangladesh has a distinct advantage in footwear production as it is involved in all stages of the value chain from raw leather to the final product. The annual export of these components is expected to reach a value of USD 5 Billion within the next decade.

The sector has been growing over the last 5 years with exports increasing by 46% in 2011 followed by healthy 25% growth in 2013. Recently, total export has exceeded USD 1 billion marks for the leather sector which has been due to rising global demand and renewed interest amongst local entrepreneurs for manufacturing footwear. Some international investors have forayed in the sector setting up factories in local Export processing Zones (EPZs).

Leather and Jute Sourcing will be a Competitive Advantage

Bangladesh produces superior quality leather from local livestock, which is subsequently processed by tanneries concentrated around the capital city. These inputs are then transformed into final products including footwear whose exports stood at USD 419 Million as of 2013. (Source: EPB)The annual production of leather hovers around 250 Million square feet each year with supply peaking during the religious festivals of Eid. In 2013 the supply of rawhide stood around 7 Million pieces with the tanneries struggling to keep up with the supply.

Bangladesh is currently the second largest producer of jute fiber. The highest quality of jute fiber is located in Bangladesh. Therefore, Bangladesh is able to supply the highest quality of jute fiber in the world. In terms of world export of jute fiber, Bangladesh’s share is more than 70%, which makes Bangladesh the largest exporter of jute fiber in the world.

Bangladesh has Robust Backward Linkages

In Bangladesh, incoming raw hides are sorted and processed in tanneries. To patronage these entities the government has built a 200 acre Leather Industrial Park in Savar including utilities at a cost of USD 60 Million. The park will include state of art Effluent Treatment Plants (ETPs) as well to treat the waste generated while processing the leather in the tanneries. Additionally, leather industry is considered blue-chip by Bangladesh Bank (BB) and recently the central bank has given leather industry a boost with relaxing policies for shifting to Savar so that footwear sector can flourish.

About The Company

Jihan Footwear (Pvt)Ltd. is one of the most renowned BSCI certified 100% export oriented manufacturers and exporters of Leather goods, Leather Footwear and Espadrilles located in Rampur, Burichong,Comilla, Bangladesh. It is a sister concern of Jihan Group. The company is engaged to make different types of Baby Sandals, Baby Slippers, Boys Sandals, Boys Slippers, Footwear, Girls Sandals, Girls Slippers, Mens Sandals, Mens Slippers, Sandals, Etc. The company was established in 2013 and production started in 2013 with daily production capacity of Espadrille shoes 6,500 pairs per day and leather shoe 8,000 pairs per day and subsequently will be increased to 13,000 and 14,000 pairs per day respectively. Since its inception in 2013 Jihan Footwear (Pvt) Ltd has always striven to develop new and revolutionary shoe products, which have played a massive role especially in Europe and African counties. Dedication, authenticity and relentless work effort on a continuous basis, has made our company to stand out in the European market. Our production are made with authentic and quality raw materials that are skillfully manufactured by our master artisans, which distinguishes us is our ongoing effort to provide the absolute best quality espadrilles with on time delivery. Our Company motto is to provide the absolute best quality shoe at very reasonable and competitive price. We believe in customer satisfaction. Jihan footwear (pvt) Ltd. has passed the “BSCI” social compliance audit and also gained Environmental management system iso-14001 certificate. It has also done electrical safety assessment by BUREAU VERITAS, achieving 2032 score out of 2237, getting result Green. It has done building safety assessment by BUET, getting result Green.

Objective

“Quality Management”, “Product Safety” and “Customer Satisfaction” are the Core of Jihan Footwear (Pvt.) Limited. “Prevention” is the core of our Quality Control System, therefore, stringent procedures of test will be carried out to all of the raw materials, including raw leather, chemicals etc; and rigorous tests to our products are conducted to ensure we have achieved buyer’s requirement and to deliver the products punctually.

Management

The overall management of the company is vested with the Board of Directors. It is a one-tier Board which provides direction for the organization; establish policies; and monitor and control overall functioning of the company. The managing director, assigned authority by the Board, holds the responsibilities to execute day to day affairs. Jihan Footwear (Pvt.) Limited has a well-defined organizational structure to run the management system in order for the objectives to be achieved effectively and efficiently.

Technical Aspects

Introduction

Production Capacity

Production Process Flow

MARKETING ASPECTS

Objective & Market Study

The project has mainly been designed to produce espadrille and leather shoes. The project’s whole output as well as services shall be exported outside the country. The objective of the Market study is to examine and investigate the demand pattern sources and uses of leather shoes and export markets & growth prospects of the same in Bangladesh.

Footwear includes:

a. Casual Shoes

b. Sport Shoes

c. Moccasins

d. Safety Boots

e. Monk

f. Oxford

g. Chappals

h. Horachi etc

Background of Industry in Bangladesh

Footwear is a traditional export item of Bangladesh. Footwear produced from high quality leather and jute in the country enjoys a good reputation worldwide for their quality. The country, however, has a growing success in this sector. The business experts believe that export earnings from the sector could be substantially increased if we use advanced technology to produce high quality footwear. The low wage rate and poor enforcement of environmental laws and rules have given the country’s footwear sector a comparative advantage in the world market. Moreover, the country enjoys duty exemption under the GSP (Generalized System of Preference) from the most of the importing countries of the developed world. Bangladesh also enjoys a reduction of Tariff and other non-Tariff barriers from WTO (World Trade Organization). While this provide an opportunity for a country like Bangladesh to boost up its export.

Bangladesh is now a promising name in the world of leather and jute industry. China is losing its attractiveness for new and established buyers. The sourcing of leather and jute shoes is experiencing a new phase of transition. Once China was considered to be the place for sourcing, the light is starting to shine even brighter on Bangladesh. In near future Bangladesh will be the most promising sourcing destination on the radars of all retailers